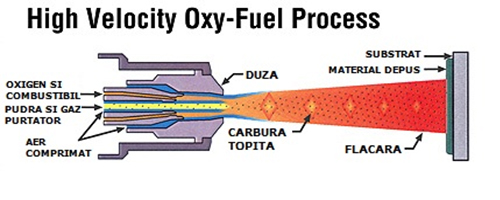

HVOF deposition process is the continuous introduction, by means of a high pressure carrier gas, of the powder metal, axially into a combustion chamber. By means of fuel gas (propane) and oxygen in the combustion chamber combustion occurs, which results in melting of powdered metal and getting a high pressure mixture followed by the expansion in the exit nozzle exit. The result is a high speed jet which is directed towards the surface of the part. Carbide particles that are mainly in a liquid state are accelerated to very high speeds which leads to obtaining particle layers deposited with high density and very good adhesion on the surface of the part.

MAIN FEATURES OF THE PROCEDURE AND OF THE DEPOSITED LAYER

- Workpiece surface temperature during the process does not exceed 150 C.

- High density: less than 2%

- High adhesion to the part: more than 82 MPa;

- Microhardness: 1100-1350HV0,3;

- Good resistance to fatigue;

- Thickness of the deposited layer is usually up to 0.3 mm;

- Excellent resistance to wear due to sliding friction, erosion, cavitation;

- Resistance to corrosion, including heat, oxidation and corrosion by alkaline and acidic media;

- Good finishing surface, which can be grinded, lapped, honed or superfinished to 0.1 Ra.

To increase resistance to corrosion and abrasion Confind uses its own procedures for sealing and densification of the carbide deposits applied by HVOF method.